Protective coatings and applications provide better protection for equipment and machinery. Understanding how these applications improve their tools and products helps businesses extend the longevity of their tools. Reviewing what to expect from parlyene coatings helps companies learn why it’s critical.

Protects Equipment from Dust

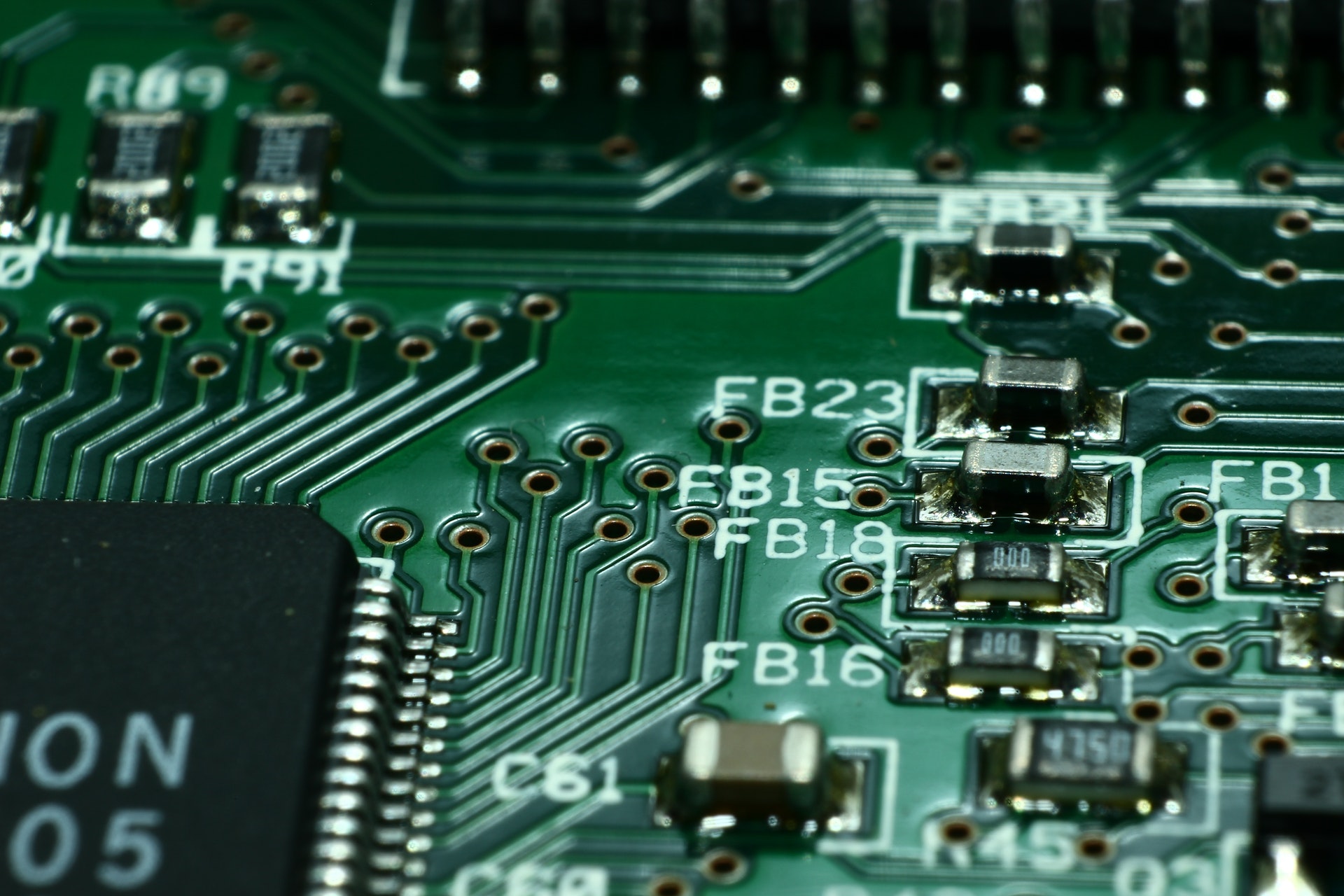

The coating protects the equipment from dust and prevents it from causing damage. Electronics need better protection against dust as it can cause serious component damage. Using parlyene helps the business owner lower risks to their equipment and use it longer. Reviewing how the coating is applied shows the business owner how effectively the application protects against dust and debris.

Prevents Equipment Damage Caused by Temperatures

Temperature changes can cause equipment changes, too. Overheating could lead to the melting of components and causing warping. If the components cannot cool down, the equipment won’t operate properly. Coating the equipment with parlyene can keep the equipment at a lower temperature and prevent the components from becoming damaged because of sudden temperature changes or overheating.

Blocks Negative Effects of Moisture

Moisture can become a serious problem for equipment and tools. Rust and corrosion can become a complex problem for businesses that use tools and equipment to operate their company. The coating blocks moisture and prevents it from collecting on or inside the equipment or tools. The protective coating makes the products last longer and gives the business owner many years of use. Business owners can read a great article to find out more about how the coatings can protect their machinery and tools more effectively.

Increases the Durability of the Equipment

With the coatings, the equipment could become more durable and withstand more force. Applying the parlyene to the surface of certain tools and machines prevents scratches and cosmetic damage, too. If materials are positioned on the equipment often, this could increase the risk of damage and cause the machine to become worn. The best applications protect the equipment and give business owners more use-value. Medical facilities need more durable products for saving lives and providing a proper diagnosis. The coatings could protect their machinery more effectively and keep it from becoming damaged too quickly.

The Coating Protects Equipment against Contaminants

Medical staff use tools, equipment, and machines each day to treat their patients. While using the products, the surfaces could come in contact with germs and contaminants that could present risks for the staff and others. Using the parlyene coatings makes it easier to clean these tools and prevent contaminants from leaking into the tools. Keeping the tools and equipment more sanitary is a requirement for all medical facilities and helps the staff mitigate more risks to their patients.

Using protective coatings on machines, equipment, and tools extends the longevity of the products and gives the owner more use-value. Understanding how the parlyene coatings work shows the owner why it is critical to apply it to all tools they use every day. The coatings are not bulky and won’t cause pinholes that threaten the integrity of the equipment. Business owners can learn more about these applications by contacting a vendor now.